Overview

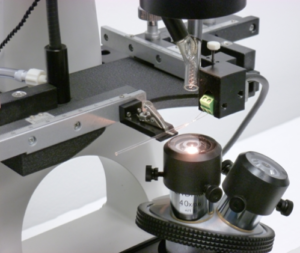

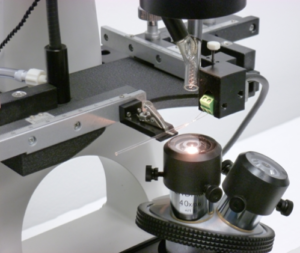

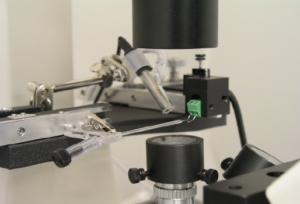

Increase efficiency and lower the cost of patch pipette production by using ALA’s CPM-2 Coating and Polishing Microforge. The CPM-2 is designed to be a complete system for processing pulled patch pipettes. It is available as a kit that mounts on a microscope or as a complete system with an inverted microscope.

Key Features of the CPM-2 include:

- Convenient control of heat timing with foot-pedal switch

- Heating and air pressure controls conveniently located in one unit

- Coating and polishing without electrode removal

- Available as complete system that includes inverted microscope with parfocal optics or as a kit

Electrophysiologists polish patch pipettes because pipette pulling often leaves sharp surfaces that can damage delicate cell membranes. Coating of pipettes is often necessary with the excised patches or cell-attached configurations to reduce noise from pipette capacitance and dielectric loss1. Pressure polishing, a innovation in pipette processing, minimizes series resistance with small-tip pipettes to facilitate whole-cell recording of small cells2.

1 Hamill, O.P. et al. Improved patch clamp techniques for high-resolution recording from cells and cell free membrane patches. Pflugers Arch. 391, 85-100 (1981).

2 Goodman, M.B. & Lockery, S.R. Pressure polishing: a method for re-shaping patch pipettes during fire polishing. J. Neurosci. Methods. 100, 13-15 (2000).

Last Updated on October 21, 2024

Details

Each CPM-2 includes the following:

Each CPM-2 includes the following:

• Air jet with heating element for curing silicone (CPM-HOTJET)

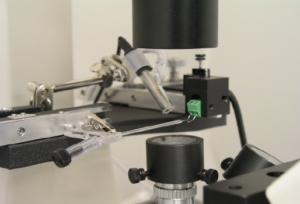

• Polishing filament (CPM-PTIR) with its own XYZ manipulator

• Control box with footswitch

The CPM-2w/scope includes everything in the CPM-2 kit as well as the KXD900 inverted microscope and XY stage manipulator (CPM-XY) for the pipette holder.

The pressure polishing option requires the PR-60, which allows for easy regulation of house or tank pressure, the CPM-PHold bracket and the IPH high pressure pipette holder.

Last Updated on October 21, 2024

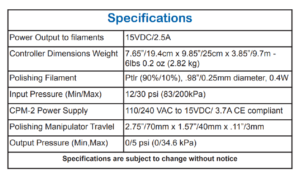

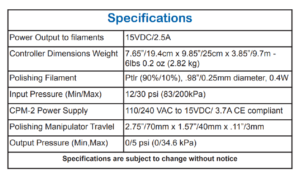

Specification

Last Updated on October 21, 2024

Downloads

CPM-2 Product Literature

CPM-2 Product Manual

CPM-2 Product Manual

Last Updated on October 21, 2024

Ordering

| Part # |

Description |

| CPM-2w/scope |

Coater/Polisher Microforge includes controller, coating & polishing filament, footswitch, XYZ polishing manipulator, pipette holder manipulator, and inverted microscope. |

| KXD900 |

CPM Microscope, without stage |

| PR-60 |

60 psi High Pressure Regulator for use in the Pressure Polishing Method |

| CPM-HOTJET |

Replacement CPM-2 Hot Air Jet |

| CPM-Polishing |

CPM polishing manipulator with Z axis polisihing filament control |

| CPM-PPHOLD |

Bracket to hold injection holder for CPM-2 microscope for pressure polishing option |

| CPM-PTIR |

PtIr polishing filament – package of 3 |

| CPMXY |

CPM-2 XY stage manipulator for pipette movement with pipette clip |

| CPM-Stage |

CPM stage assembly for use on KXD-900 microscope, includes CPM XY, CPM polishing and Hot Air Jet |

| IPH-THP |

Pressure electrode holder for use with pressure polishing technique |

Last Updated on October 21, 2024

Research Articles

Culturing and patch clamping of Jurkat T cells and neurons on Al2O3 coated nanowire arrays of altered morphology

Somatosensory Neurons Enter a State of Altered Excitability during Hibernation

Rapid active zone remodeling consolidates presynaptic potentiation

Grasskamp, A. t., Jusyte, M., McCarthy, A. W., Götz, T. W. B., Ditlevsen, S., Walter, A. M. (2023) Spontaneous neurotransmission at evocable synapses predicts their responsiveness to action potentials. https://doi.org/10.3389/fncel.2023.1129417

Last Updated on October 21, 2024