Overview

The OctaFlow II ™ from ALA is our most advanced drug application device for electrophysiology and imaging research. This fast perfusion system is designed to meet the needs of basic science and drug discovery researchers. Software control of all perfusion parameters makes the OctaFlow II ™ superior to all other perfusion systems.

The OctaFlow II ™ from ALA is our most advanced drug application device for electrophysiology and imaging research. This fast perfusion system is designed to meet the needs of basic science and drug discovery researchers. Software control of all perfusion parameters makes the OctaFlow II ™ superior to all other perfusion systems.

Key features of the OctaFlow II ™ include:

-

- Choice of low-maintenance pinch valves or fast-response isolation valves

-

- Valve-control of solution flow instead of motorized manipulation of barreled pipettes, minimizing sample losses following solution exchange

-

- Keyboard solution selection, for exchange “on the fly”

-

- Trigger in /out for synchronization with data acquisition systems

-

- Preprogrammed solution delivery through software

-

- Rapid flush mode for easy cleaning

-

- Programmable pressurization of fluids for optimal solution flow

-

- Programmable analog outputs for valve identification, step number, or pressure information to data acquisition

Each OctaFlow II ™ system allows for a choice of 8, 16, 24 or 32 reservoirs, which can be configured in different modes, depending on the experiment(s). Constant perfusion can be achieved through the combination of compound application and wash solution for minimization of solution convergence in manifold. Periodic application of compounds can be achieved through specific focal application. U-tube and J-tube configurations are also possible with the Octaflow II™.

The OctaFlow II ™ software runs on Windows 7 (64-bit) or Windows 10 and communicates with the PC via USB 2.0. Sequence steps are loaded at USB 2.0 speeds for fast editing and executing of sequence files. The graphical interface is designed to control all perfusion parameters from a single window. It also allows you to create configuration files and sequence files and to save them for future use. The Cleaning Manager function in the software allows for fast cleaning of reservoirs, valves and tubing.

Last Updated on November 25, 2025

Details

Each OctaFlow II ™system includes the following:

-

- Magnetic stand with one pole

- Valve manifold(s) with isolation or pinch valves and 5mL pressurized syringe reservoirs

- Flush valve(s)

- Quartz MicroManifold® perfusion outlet manifold(s) in various configurations (see below)

- 230um ID and 600um OD Teflon tubing (FEP-1) and compression fittings (CF-1) for 1/16″ ID tubing (other sizes available – see below)

- USB cable and software

Each OctaFlow II ™ system features a choice of valves:

-

Pinch valves : The 3-way normally open and normally closed pinch valves require minimal maintenance in long-term perfusion experiments and have response times of 15-20 ms.

Pinch valves : The 3-way normally open and normally closed pinch valves require minimal maintenance in long-term perfusion experiments and have response times of 15-20 ms.

-

Isolation valves : The 2-way normally closed isolation valves are optimized for high-speed solution exchange. These valves are completely isolated when closed and have response times of 3-4 ms.

Isolation valves : The 2-way normally closed isolation valves are optimized for high-speed solution exchange. These valves are completely isolated when closed and have response times of 3-4 ms.

Additional options include:

-

- CF-2: Compression fitting for PE-20/FEP-2 tubing to 1/16″ ID tubing

- FEP-2: Clear Teflon tubing with 380um ID and 760um OD

- QMM-8: Quartz MicroManifold® 8 to 1 channel perfusion outlet manifold with 100um or 200um ID polyimide-coated quartz tubing and tip (other sizes available)

- QMM-16: Quartz MicroManifold® 16 to 1 channel perfusion outlet manifold with 100um or 200um ID polyimide-coated quartz tubing and tip (other sizes available)

- QMM-24: Quartz MicroManifold® 24 to 1 channel perfusion outlet manifold with 100um or 200um ID polyimide-coated quartz tubing and tip (other sizes available)

All of the Quartz MicroManifold® perfusion outlet manifolds are also available with an additional channel with 200um ID tube for flushing dead space and/or with Teflon tubing installed.

Last Updated on November 25, 2025

Specifications

- Maximum number of perfusion valves: 32

- Suction developed via internal Venturi pump: 199 mmHg nominal

- Maximum number of valves per bank: 8 valves/bank, up to 4 banks

- Typical speed of pressure rise: 520mmHg/sec

- Maximum current output per valve: 100mA/ 350mA isolated/pinch valve

- Pressures selectable in mm/Hg in increments of 1 or other units selectable

- Maximum voltage/valve: 18V

- Sample flow rate: 1ml in 9 min. @ 520 mmHg with standard QMM

- Maximum on time per valve: no limit

- Minimum on time per valve: 7ms @ 12V & 1ms @ 18V

- Standard QMM = QMM-8/1wt: 8 tubes with 100μm ID, 1 tube with 200μm ID, 100μm ID tip

- Maximum input pressure: 3970mmHg – other units selectable

- Tip sizes available: 100, 150, 200 μm ID

- Maximum pressure applied: ~800mmHg

- Maximum number of sequence steps: 300

- Power requirements: 120/220V

- Maximum number of sequence events with looping: 30020

- OctaFlow interface: 19″x3.5″x10″, 10 lbs/4.5kg

- Infinite Step Function in Repeat Mode

- Programmable Voltage Range: 1-22volts/valve

- USB 2.0: Support Software is compatible with Windows 7 (64 bit) and Windows 10

|

Pinch Valve |

|

| 3 way |

NO/NC port |

NC port |

| Response time |

15 to 20ms |

2 to 5ms |

| Wetted area |

silicone tubing |

PTFE |

| Voltage |

12V |

12V |

| Power |

4.2W |

1W |

Last Updated on November 25, 2025

Accessories/Replacement Parts

Accessories:

- Microscope Stage Plate and Tool Holders: microscope stage insert and perfusion tool holders

- VWK: Vacuum Waste Kit

- SFK: miscellaneous tube and luer fittings

- ALA Quartz MicroManifold® (QMM-8/16/24/WT): perfusion outlet manifolds with 100um or 200um ID (please specify) tubing and tip (other sizes available – please call or email to inquire)

- ALA FEP-1: 4m clear Teflon tubing with 230um ID and 600um OD (for 100um ID QMM’s)

- ALA FEP-2: 4m clear Teflon tubing with 380um ID and 760um OD (for 200um ID QMM’s)

- ALA CF-1: Compression fitting for PE-10/FEP-1 tubing to 1/16″ ID tubing

- ALA CF-2: Compression fitting for PE-20/FEP-2 tubing to 1/16″ ID tubing

Replacement Parts:

- ALA 10mlRES: 10mL pressurized reservoir assembly with 3-way luer valve

- ALA 5mlRES: 5mL pressurized reservoir assembly with 3-way luer valve

- ALA PV: Replacement pinch valve

- ALA CL: Replacement Clippard Isolation valve

- ALA CLP3V: Replacement 3-way isolation flush valve

- ALA CLP3VB: Replacement 3-way isolation flush valve with LED

– Contact ALA for questions on Accessories and ordering of Replacement Parts

Last Updated on November 25, 2025

Downloads

OctaFlow II Literature

OctaFlow II Literature

Daily Usage manual

Daily Usage manual

OctaFlow II Software Manual

OctaFlow II Software Manual

Octaflow II Software for Windows 10 64 bit systems

Customer Supplied Matlab based Octaflow control app

Last Updated on November 25, 2025

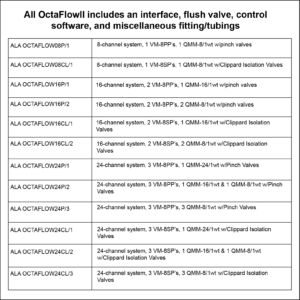

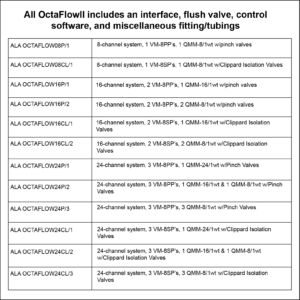

Ordering

Last Updated on November 25, 2025

The OctaFlow II ™ from ALA is our most advanced drug application device for electrophysiology and imaging research. This fast perfusion system is designed to meet the needs of basic science and drug discovery researchers. Software control of all perfusion parameters makes the OctaFlow II ™ superior to all other perfusion systems.

The OctaFlow II ™ from ALA is our most advanced drug application device for electrophysiology and imaging research. This fast perfusion system is designed to meet the needs of basic science and drug discovery researchers. Software control of all perfusion parameters makes the OctaFlow II ™ superior to all other perfusion systems.