Overview

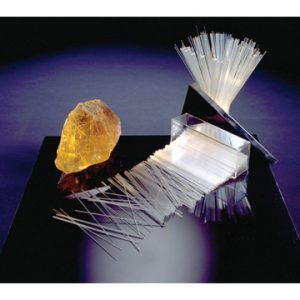

Increase efficiency and lower the cost of patch pipette production by using ALA’s CPM-2 Coating and Polishing Microforge. The CPM-2 is designed to be a complete system for processing pulled patch pipettes. It is available as a kit that mounts on a microscope or as a complete system with an inverted microscope.

Key Features of the CPM-2 include:

- Convenient control of heat timing with foot-pedal switch

- Heating and air pressure controls conveniently located in one unit

- Coating and polishing without electrode removal

- Available as complete system that includes inverted microscope with parfocal optics or as a kit

Electrophysiologists polish patch pipettes because pipette pulling often leaves sharp surfaces that can damage delicate cell membranes. Coating of pipettes is often necessary with the excised patches or cell-attached configurations to reduce noise from pipette capacitance and dielectric loss1. Pressure polishing, a innovation in pipette processing, minimizes series resistance with small-tip pipettes to facilitate whole-cell recording of small cells2.

1 Hamill, O.P. et al. Improved patch clamp techniques for high-resolution recording from cells and cell free membrane patches. Pflugers Arch. 391, 85-100 (1981).

2 Goodman, M.B. & Lockery, S.R. Pressure polishing: a method for re-shaping patch pipettes during fire polishing. J. Neurosci. Methods. 100, 13-15 (2000).

Last Updated on January 12, 2022

Details

Each CPM-2 includes the following:

Each CPM-2 includes the following:

• Air jet with heating element for curing silicone (CPM-HOTJET)

• Polishing filament (CPM-PTIR) with its own XYZ manipulator

• Control box with footswitch

The CPM-2w/scope includes everything in the CPM-2 kit as well as the KXD900 inverted microscope and XY stage manipulator (CPM-XY) for the pipette holder.

The pressure polishing option requires the PR-60, which allows for easy regulation of house or tank pressure, the CPM-PHold bracket and the IPH high pressure pipette holder.

The pressure polishing option requires the PR-60, which allows for easy regulation of house or tank pressure, the CPM-PHold bracket and the IPH high pressure pipette holder.

Last Updated on January 12, 2022

Specification

Power Output : 27VDC / 2.5A

Controller Dimensions: 7.65″ W x 9.85″ L x 3.85″ D

Polishing Filament Material: Platinum / Iridium (90%/10%)

Polishing Filament Size: 0.25mm diameter

Polishing Filament Resistance: 4 Ohms

Minimum Input Pressure: 12 psi / 83 kPa

Maximum Input Pressure: 30 psi / 200 kPa

Power Input: 110-120/220-240VAC ~.5/.25A, 60/50Hz

Weight: 6 lbs. 0.2 oz.

Last Updated on January 12, 2022

Downloads

CPM-2 Product Literature

CPM-2 Product Manual

CPM-2 Product Manual

Last Updated on January 12, 2022

Ordering

| Part # |

Description |

| CPM-2w/scope |

Coater/Polisher Microforge includes controller, coating & polishing filament, footswitch, XYZ polishing manipulator, pipette holder manipulator, and inverted microscope. |

| KXD900 |

CPM Microscope, without stage |

| PR-60 |

60 psi High Pressure Regulator for use in the Pressure Polishing Method |

| CPM-HOTJET |

Replacement CPM-2 Hot Air Jet |

| CPM-Polishing |

CPM polishing manipulator with Z axis polisihing filament control |

| CPM-PPHOLD |

Bracket to hold injection holder for CPM-2 microscope for pressure polishing option |

| CPM-PTIR |

PtIr polishing filament – package of 3 |

| CPMXY |

CPM-2 XY stage manipulator for pipette movement with pipette clip |

| CPM-Stage |

CPM stage assembly for use on KXD-900 microscope, includes CPM XY, CPM polishing and Hot Air Jet |

| IPH-THP |

Pressure electrode holder for use with pressure polishing technique |

Last Updated on January 12, 2022

Each CPM-2 includes the following:

Each CPM-2 includes the following: The pressure polishing option requires the PR-60, which allows for easy regulation of house or tank pressure, the CPM-PHold bracket and the IPH high pressure pipette holder.

The pressure polishing option requires the PR-60, which allows for easy regulation of house or tank pressure, the CPM-PHold bracket and the IPH high pressure pipette holder.